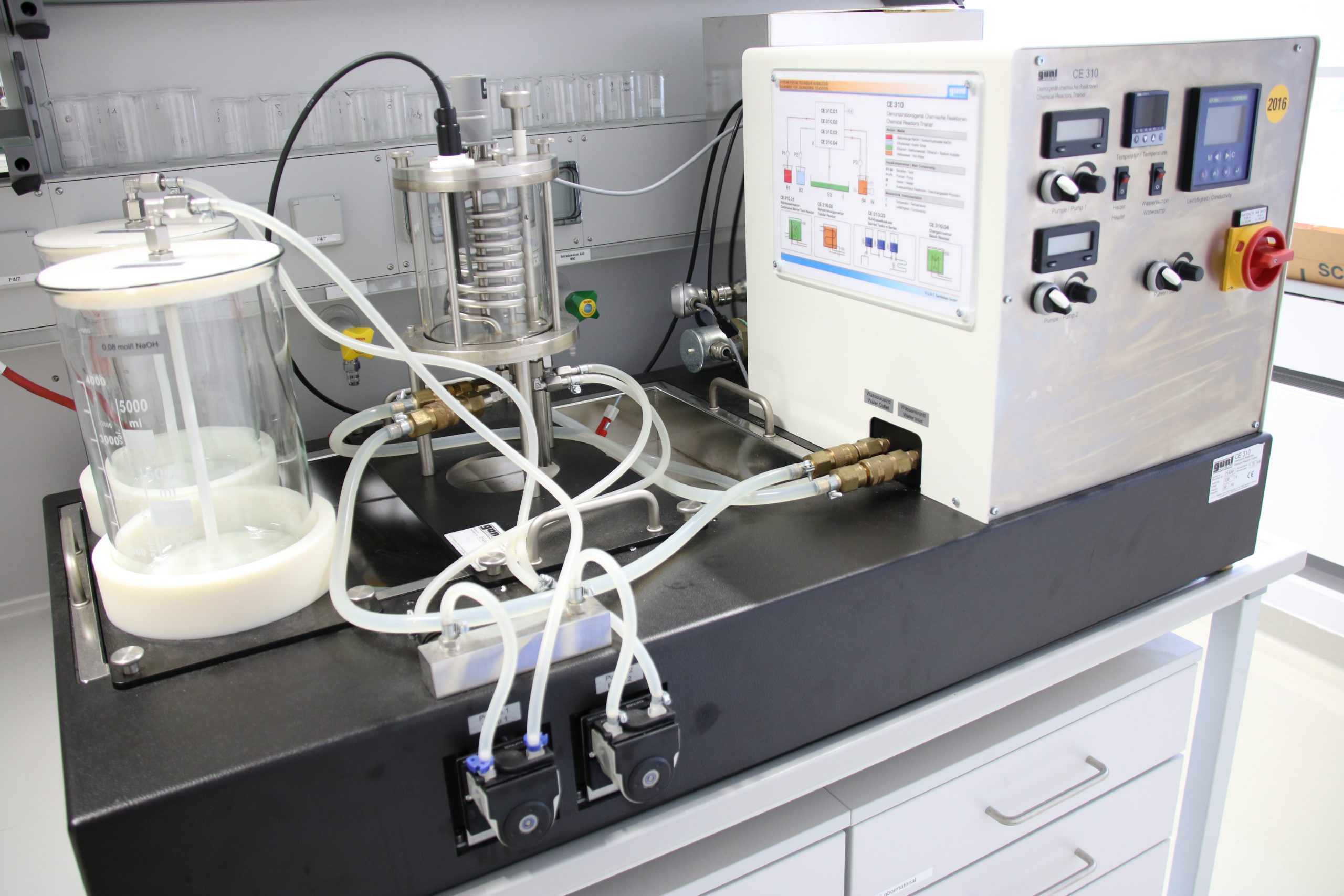

Our Laboratory

Waste solutions from catalytic processes in chemistry can be very valuable if they contain catalysts containing precious metals – even in very low concentrations. A closed precious metal cycle is getting closer with a ‘chemical magnet’, a new recycling method.

Precious metals such as platinum or rhodium are very valuable, but also very rare. Because, due to the constantly increasing demand for precious metals, it has long been impossible to cover the demand solely by extracting ore from the mines, recycling is becoming increasingly important. In the chemical industry, for example, numerous catalytic processes produce large quantities of liquid residues that contain low concentrations of dissolved noble metal catalysts. So far, low-concentration precious metal-containing waste solutions could hardly be recycled or not economically. With the new adsorption process from ANGA.AG, these can now be processed efficiently. Since this is possible even with initial precious metal contents of the process solutions in the single-digit ppm range (ppm = parts per million), even the smallest amounts of precious metal are now retained in the precious metal cycle in a resource-saving manner and can be recycled in an environmentally friendly manner.

The chemical process should allow the efficient processing of even extremely low-concentration waste solutions containing precious metals. In the process, we pull the finely distributed residues containing precious metals out of the solution as if with a ‘chemical magnet’. The noble metal is bound to the surface of the adsorbent. We can then prepare the materials with the valuable content using wet-chemical processes in such a way that the pure precious metal is available again at the end. In principle, the chemical process can be applied to all precious metals. This technology has already been used successfully with highly diluted organic platinum solutions or rhodium solutions from homogeneous catalytic processes in the chemical industry. Although rhodium is mainly required in the automotive industry for exhaust gas catalytic converters, it is also widely used in the chemical industry due to its outstanding catalytic properties. Homogeneous catalytic processes with rhodium play an important role in the production of special chemicals (e.g. plasticizers, acetic acid, acetic anhydride, active pharmaceutical ingredients). Platinum catalysts are important in silicone manufacture.